A Resource Still Being Wasted

In a world racing toward energy transition and building a green economy, resource waste can be considered an economic crime. According to a shocking new report from the United Nations Institute for Training and Research (UNITAR), an estimated $10 billion worth of precious metals is being senselessly wasted every year, sitting in piles of electronic waste (e-waste) across the planet. This figure is not only a massive financial loss but also a strategic waste of key materials vital for the future of clean industries and high technology.

The report, published on October 12, highlights an alarming reality: the majority of this waste comes from so-called “invisible” e-waste—small items that are often overlooked in formal collection and recycling campaigns. These include everything from electronic toys, old cables, e-cigarettes, power tools, electric toothbrushes and shavers, to headphones and other small household items. These devices contain metals such as gold, silver, copper, and especially lithium—strategic raw materials that are indispensable for manufacturing electric vehicle batteries, renewable energy equipment, and communication devices.

The world is witnessing an explosive demand for these metals. In Europe alone, for example, the demand for copper is projected to increase six-fold by 2030. This demand is the driving force behind the development of renewable energy, aerospace, defense, and, of course, the electric vehicle revolution. However, instead of utilizing the abundant potential supply from e-waste, the global e-waste recycling rate has plummeted to a dismal 17%. This stark contrast raises an urgent question: Why is humanity accepting the waste of such a valuable resource, and what is the solution to this invisible resource crisis?

The Shocking Reality

UNITAR estimates that the amount of “invisible” e-waste worldwide currently totals 9 million tonnes per year, equivalent to wasting about $9.5 billion in precious metals. The $10 billion wasted is not merely money; it is the market value of materials that, if recovered, would reduce the pressure on natural resource extraction, minimize environmental pollution, and ensure supply chain stability.

The Alarming Recycling Rate and Resource Threat

The 17% recycling rate is an indicator of the failure of current waste management systems. With the rate of e-waste generation rapidly increasing in many countries, including Vietnam, the drop in the recycling rate means that more and more valuable materials are being landfilled, polluting soil and water with hazardous substances such as lead, mercury, and cadmium.

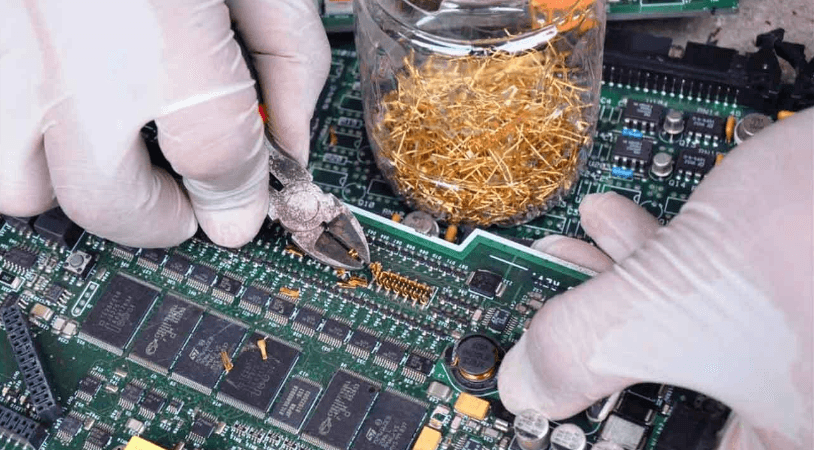

Precious metals like gold and silver have a much higher concentration in e-waste than in mined ore. One ton of old mobile phones can contain tens of times more gold than one ton of gold ore. The wastage of these “urban mines” demonstrates a shortfall in both awareness and macro-level policy.

Strategic Metal Composition

Small electronic items are a treasure trove of critical elements:

- Copper (Cu): An essential electrical conductor for all types of cables, motors, and energy transmission systems. The surge in copper demand is the clearest indicator of global electrification.

- Lithium (Li): The core element in Lithium-ion batteries, the driving force behind electric vehicles and renewable energy storage. Wasting small battery-containing devices (like e-cigarettes or wireless headphones) is directly contributing to the depletion of the global Lithium supply.

- Gold (Au) and Silver (Ag): Used in circuit boards and microchips to ensure optimal conductivity and corrosion resistance.

This wastage is not just missed revenue; it is a risk to future resource security. Nations will have to compete more intensely to extract primary supply (mining) while the secondary supply (recycling) is being neglected.

The Strategic Role of Precious Metals and the Green Economy

The green economy is not just about reducing carbon emissions; it is about building a circular economic system where resources are used most efficiently. The precious metals wasted in e-waste are the “lifeblood” of the green economy.

The Engine of Energy Transition

The shift from fossil fuels to renewable energy requires a large amount of metal infrastructure. Solar panels, wind turbines, smart grid systems, and most importantly, energy storage batteries, all rely on copper, lithium, nickel, cobalt, and rare earth metals.

The forecast for a six-fold increase in copper demand in Europe by 2030 is not just a number; it is a calculation of the material needs to build a carbon-free continent. Without a stable metal supply from recycling, the green transition will be hampered by rising extraction costs, price volatility, and dependence on complex geopolitical supply chains.

Resource Security and Sustainability

In the context of geopolitical tensions, ensuring the supply chain of critical raw materials becomes a top priority. Recycling e-waste from “urban mines” provides resource independence for nations. Every recovered gram of metal is a gram that does not need to be mined from the earth abroad, helping to reduce supply chain risks, minimize the environmental impact of traditional mining (which often causes severe pollution), and decrease reliance on major metal-producing nations.

This $10 billion waste shows that the world is actively undermining its own sustainable development goals. Recycling is not merely environmental protection; it is a smart economic strategy and a pillar of resource security.

The Origin and Challenges of “Invisible” E-Waste

The core problem identified by the UNITAR report is the existence of “Invisible Waste.” These are small devices that are easily forgotten or stored away instead of being recycled.

Consumer Behavior and “Hoarding”

A large portion of invisible e-waste is due to consumer habits. Instead of recycling, many people keep old cables, broken headphones, outdated mobile phones, or unused electric toothbrushes in drawers with the mindset of “I might need it someday.” When they are finally discarded, they are often treated as regular household waste instead of e-waste and end up in landfills.

Collection and Sorting Challenges

Small items like USBs, charging cables, or electronic toys have a low metal value per unit of mass, making them less attractive to large-scale recyclers. The cost of collecting and sorting these tiny items is much higher than processing large appliances like refrigerators or washing machines.

Current waste collection systems are often designed for bulky household waste or large consumer electronics. They lack specialized, easily accessible collection points for small items, creating a behavioral barrier for consumers who want to recycle.

Product Design and Durability

Another issue is the trend of product design that is not easily disassembled or repaired (e.g., soldered batteries, use of glue instead of screws). This not only reduces the product’s lifespan but also makes the extraction of precious metal components more complex and costly for recyclers.

Vietnam’s Perspective and the Opportunity for Transformation

For a rapidly developing nation like Vietnam, the fast-growing e-waste problem is a major challenge, but also an economic opportunity.

Growing Challenges

Vietnam is undergoing rapid urbanization and increasing electronic consumption. E-waste in Vietnam is often processed through an informal, spontaneous recycling system. While this system creates livelihoods for many people, it poses a serious risk of environmental pollution due to rudimentary metal extraction methods (such as burning cables for copper) that release toxic substances.

The waste of precious metals in Vietnam may be even higher than the global average, due to the lack of high-tech processing plants to thoroughly extract strategic metals from complex waste.

Opportunities for Transformation and Innovation

Vietnam can leverage this e-waste crisis to take the lead in adopting the circular economy model:

- Attracting Investment: Invest in modern, high-tech factories to extract gold, copper, and lithium from e-waste (similar to the “Gold Extraction from E-Waste Factory” model previously mentioned).

- Formalizing Recycling: Support and upgrade the existing informal recycling system, providing safer and more efficient technology to simultaneously ensure livelihoods and protect the environment.

- Supporting the Disabled: Develop innovative programs like “Turning E-Waste into Assistive Devices for the Disabled,” transforming scrap materials into products with high social value.

Solutions and the Path to a Circular Economy

To address the $10 billion waste problem, a systemic shift from the linear economic model (take-make-dispose) to a circular economy model is mandatory.

Extended Producer Responsibility (EPR) Policy

EPR is a critical policy tool that mandates producers to be responsible for their products after they reach the end of their lifespan. Governments need to establish strict EPR regulations, including for small electronic devices. This will create a financial incentive for companies to design more recyclable products and invest in effective take-back systems for “invisible” waste.

Technological Innovation and the Recycling Industry

A breakthrough in e-waste processing technology is necessary. Advanced hydrometallurgical and pyrometallurgical extraction technologies can recover up to 99% of precious metals. Building large-scale e-waste processing centers that employ this technology will transform e-waste into a reliable resource.

Raising Community Awareness and Designing Collection Systems

Governments and NGOs need to cooperate to raise awareness about the value of small electronic items. Collection campaigns must be easy, convenient, and accessible to the public. Establishing specialized collection points at supermarkets, schools, and apartment buildings for small items like batteries, cables, and headphones is a necessary step to bring “invisible” waste into the recycling stream.

A Vision for a Sustainable Future

The wastage of nearly $10 billion in precious metals every year in e-waste is not just a heartbreaking figure, but clear evidence of the inefficiency of the current consumption and production model. In the global race towards green energy and digital transformation, missing out on this strategic resource is a self-imposed obstacle.

However, opportunity always lies within a challenge. The UNITAR report is a powerful wake-up call. By thoroughly applying the principles of the circular economy, from EPR policies, investment in recycling technology, to changing consumer behavior, the world can turn the piles of “invisible” e-waste into abundant “urban mines,” securing the supply of strategic metals, protecting the environment, and shaping a greener and more sustainable economic future.

Source: tuoitre and compiled from the internet.

Related Posts

Vietnamese Lunar New Year A Cultural Beauty That Honors Ancestral Roots And The Sacred New Year’s Eve

HAPPY LUNAR NEW YEAR – VMRF

Repealing the 2009 Endangerment Finding: The First Move in a Long Planned Effort to Rebuild America’s Metallurgical Base

List of Permitted Scrap Imports: A Policy Adjustment to Tighten Environmental Control and Reshape Industrial Raw Material Supply Chains

Tightening Scrap Temporary Import and Re-export: Vietnam Proactively Blocks the Risk of Becoming a Global “Dumping Ground”

Import Policy Trends for Industrial Metal Scrap and Metal-Bearing Waste in Southeast Asia